We’ve gotten a lot of questions about what sets the Mallett Supercharger system apart from the competition. Aside from our commitment to using premium parts and proprietary engineering techniques, the primary difference comes from the blower used in the system.

We use an Eaton TVS blower pictured here:

It looks different from most superchargers you might have seen because it IS different from most superchargers. A centrifugal blower, found in many supercharger kits already on the market, takes longer to get up to speed, resulting in less overall power on the low end. In fact, centrifugal setups often generate less power than stock engines at low RPM because power is needed to drive them, even when they’re not generating boost.

The TVS blower, on the other hand, works more like an air pump than a fan. It starts generating additional power as soon as the throttle blade opens. This translates into zero lag and a much wider operating range, resulting in power increases from idle to redline. You push the pedal, you have the power – it’s just that simple. We’re talking 300 horses to the rear wheels at 2700rpm. You won’t get that from any other blower.

Additionally, our TVS blowers run at a lower internal speed and have a bypass valve, requiring less overall power to drive. Even better, these blowers can be “disconnected” when you’re not on the throttle – (it only takes approximately one horsepower to drive the blower when it’s bypassed). The increased low-end torque and decreased parasitic loss is the reason we see improved fuel efficiency and gained miles per gallon in our CARB testing.

When we looked at the way the transmission shifts, the way these trucks are used, and the overall driving experience, the TVS blower was the only option.

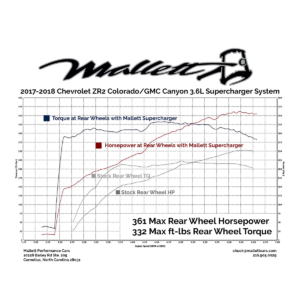

To help demonstrate the difference between the various solutions out there, take a look at the dyno numbers that show Stock (red), our TVS-powered kit (green) and Centrifugal power (blue). We drew the centrifugal data by hand to illustrate the differences.

First look at the stock curves for reference. You know how your stock truck feels, how it shifts, etc. You probably drive around all day between 1200 and 3500rpm. Maybe sometimes you confuse the transmission and it struggles to find the gear you want. Keep your typical, day-to-day driving in mind as we look at the other curves.

Now look at our curve (green). The torque curve jumps from zero to 275lb-ft between 2000 and 2250rpm. That’s how long it took the throttle blade to go from zero to 100% after the operator pushed the pedal. From there, the torque curve is pretty flat. We hit 300lbft at 2700rpm. 310 at 4000. Maxed out at 5000rpm. It’s clear to see how the TVS blower generates a lot more torque than stock at all times. It really helps the transmission as well, since you’ve got enough torque to go, even if it’s in a taller gear than you’d like. It already has the torque, so the engine doesn’t have to shift and rev to get there.

By contrast, the centrifugal curve (blue) doesn’t generate torque at low RPM. You can see how from 3000 to 3500rpm is pretty flat. It looks like the operator is rolling into the pedal. Looks like the throttle blade hits 100% at 3500rpm, and then torque climbs linearly from 3500 to 4000rpm. That’s the centrifugal lag we talked about before. When compared to the stock curve, it’s clear that the centrifugal blower makes less torque than stock, not reaching 300lbft of torque until almost 4500rpm. Torque and horsepower look good after that, but that’s a significant difference when you spend most of the time between 1200 and 3500rpm.

You have to drive the truck to really understand it, but it’s clear where the gains are here.

If you have any additional questions, please reach out via our contact form or email [email protected]